Standard 100 by OEKOTEX is a global uniform system of testing methods, criteria, and limits for harmful chemicals, which is used to certify textile products as safe for health. Standard 100 by OEKOTEX – tested for harmful substances – is a label that can be applied to products like ARStyle Inks.

“Our inks go beyond the functionality of the inks; they are also designed to meet the creative requirements of fashion companies. With their vibrant colours and excellent colour retention, our inks bring a new dimension to designs. This makes them more captivating and eye-catching. Whether printing in on cotton, or synthetic cotton blend fabrics, our inks deliver outstanding results, ensuring that your fashion creations stand out from the crowd,” Tom Strähnz, managing director A2i Germany, said.

In addition to the four CMYK colours, A2i’s R&D team has focused on white, advancing technological progress through the use of advanced water-based polymers, the company said in a press release.

“White is a must in textile applications. It is used as a background for the fabric and plays a vital role in bringing out the colors. We paid particular attention to the white of ARStyle, which is more stable than most. It also makes it easier to prepare for reprinting. The white ink’s stability allows for an optimized restart time following production breaks. Whether it is a short break or an extended pause, users can rely on the reliability of our white ink to maintain consistent performance and minimise disruption to workflow,” Giovanni Manca, Head of Ink Development, said.

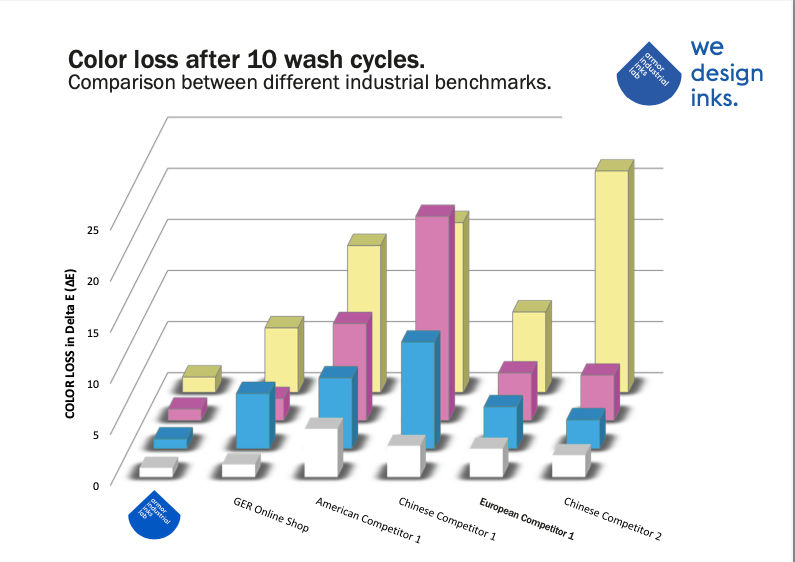

A2i conducted its own tests, adapted to the ISO 6330 method – Textiles-Domestic washing and drying methods. And the results show that colour loss after 10 washes at 40°C for a 150min cycle is minimal compared to five competitors.

The properties of our inks enable the colours to remain vibrant for a much longer period, which is not only a quality challenge but also impacts on sustainability. The consumers will keep their garment much longer, which is essential in a world where the consumption of garments is one of the largest emitters of greenhouse gases,” Strähnz concluded.

The company will be participating in FESPA international trade fair in Munich from May 23-26, 2023.

Fibre2Fashion News Desk