There are various positives for EFI in 2022, says Jeff Jacobson, CEO and chairman, Electronics For Imaging (EFI). “With 50 installations worldwide, the Nozomi single-pass product line continued to face out globally,” he says. On this interplay, Jacobson discusses progress in Fiery, its development in textile, print’s digital transformation and the way Covid accelerated that transformation even within the corrugated packaging area, because it moved on a regular basis buying exercise into the realm of eCommerce.

PrintWeek (PW): 2022 is behind us. What does your 2022 report card say?

Jeff Jacobson (JJ): EFI is at present evaluating our progress and exercise by means of the 12 months. We’ve not had our last exams fairly but so maybe it’s unfair to grade it. However once I talk about our exercise and progress in 2022 quickly – on the town halls with our employees and in conferences with our traders – a lot of the dialogue shall be about our strengthened dedication and function as a print and packaging know-how chief. We started 2022 with a realignment – together with spinning off our MIS/ERP enterprise – to completely deal with the analogue-to-digital transformation whereas creating new alternatives in industrial print.

PW: What are the positives?

JJ: There have been many in 2022. Packaging, with our Nozomi single-pass product line continued to face out globally. We’re approaching 50 installations worldwide, together with a brand new, extra compact 1.4-metre large Nozomi mannequin.

Our Fiery enterprise additionally launched a major new partnership to develop Fiery digital entrance ends (DFEs) for Fujifilm Enterprise Innovation’s Revoria digital presses in APAC and in most of Europe.

We additionally made two acquisitions final summer time to develop in our digital management capabilities, with the Fiery enterprise buying one in every of North America’s high direct-to-garment and direct-to-film digital workflow suppliers, CADlink, and our Reggiani enterprise shopping for the world’s main textile RIP developer, Inèdit.

Our leaders throughout EFI labored to deal with robust provide chain challenges, setting the desk for 2023 because the backlog attributable to the availability chain points flows by means of. Upgrades are in course of at our plant in Spain the place we make lots of our show graphics and industrial printers. And, in Italy, the place our EFI Reggiani textile operations are situated, we broke floor on a brand new facility close to Milan that may take power effectivity to a brand new, greater stage for printer manufacturing when it opens in 2023.

PW: The years 2020 to 2022 have been risky. How has it been for you, enlargement or establishment?

JJ: The previous two years have been something however establishment. In fact, the previous two years have been totally different due to Covid, lockdowns, the struggle in Ukraine, provide chain points, inflation at ranges not seen in 40 years, and extra, and we recognise the impression all of that has had on the trade. However that doesn’t imply you possibly can fail to innovate and make progress. You merely can not successfully method the digital printing market from a establishment mindset. In truth, in segments reminiscent of show graphics and packaging, demand has stayed sturdy.

There’s a lot alternative forward for print’s transformation to digital. And, within the corrugated packaging area, Covid accelerated that transformation because it moved on a regular basis buying exercise into the realm of eCommerce. Our prospects utilizing EFI Nozomi single-pass inkjet packaging presses proceed to document double-digit proportion annual will increase in output, on common, due to the fast price of change.

PW: In case you return two full years to the start of 2020, at that time, it was your first 12 months as EFI’s CEO. What are the teachings learnt?

JJ: For me personally, there was a number of investigating, studying and sure, change. I had sufficient information about EFI contemplating that I had partnered with EFI in my roles previous to turning into CEO. The essential factor for me was to take a deep dive in our markets, our alternatives and extra. We realized that one of the best step ahead concerned establishing a good stronger deal with digital print. And to do this, we invested extra assets to companies and know-how capabilities for our Fiery and inkjet merchandise in order that

our prospects can take the complete benefit of digital print’s promising alternatives.

PW: What does the idea of buyer improvement imply to you? What’s the coolest buyer improvement case research you possibly can share with us?

JJ: PrintWeek readers might find out about Avantika Printers and the best way it has developed and thrived by staying on the vanguard. The corporate first adopted EFI Fiery DFEs in 2008 and since then has earned PrintWeek’s Greatest Digital Printer Award a number of occasions. Fiery has a wonderful schooling, coaching and certification programme, and Avantika’s director Himanshu Pandey is a Fiery-certified knowledgeable who has established his firm as chief in digital color administration. At first, that stage of color administration experience helped Avantika get forward within the photobook market.

And, in 2022, Avantika took its stage of experience a step additional to handle packaging purposes at its Better Noida facility. The enterprise is likely one of the first on this planet to attain Ghent PDF Output Suite 5.0 Conformance Certification utilizing a brand new service EFI developed in collaboration with the Ghent Workgroup.

Clients like Avantika that embrace digital and actually divulge heart’s contents to the probabilities that include evolving applied sciences develop a status for excellence. And, when a print enterprise can try this and develop into one of the best in its subject, it creates a aggressive benefit that may open the door to continued development and innovation.

PW: The Ok in Dusseldorf and Labelexpo in India concluded on a excessive notice. Three essential exhibitions are lined up in 2023 and 2024, Labelexpo Europe in Brussels plus Interpack/Drupa in Dusseldorf. What ought to we count on from you at these exhibits?

JJ: In the case of tradeshows, count on sturdy attendance. Folks weren’t absolutely glad with digital occasions over the previous few years, and so they appear to be popping out to tradeshows consequently. I noticed it myself within the crowds, and gross sales above forecast, we had with Printing United within the USA.

We have been current in Better Noida, exhibiting essential industrial textile options at India ITME. India and all of South Asia are essential for our EFI Reggiani industrial textile enterprise, and textile – a market with comparatively little digital print however super development alternative – has develop into a key space of funding for us.

Whereas the exhibits you talked about are essential for the trade, at EFI, there’s additionally one other vital occasion. Our Reggiani enterprise is exhibiting at ITMA in Milan in June, and it is going to be EFI’s largest tradeshow of 2023. After which, in fact, we’re additionally wanting ahead to Drupa 2024. Whereas I can’t disclose something, Drupa has the potential to be a game-changer when it comes to the digital applied sciences we are going to current to our prospects, significantly within the show graphics and packaging areas.

PW: Are paper, paperboard and label converters nonetheless managing enterprise and manufacturing operations with industrial-age practices regardless of being part of the information age? Is there a information hole in our trade? How will we bridge it? How will we persuade Gen Z in regards to the clout of ink on paper?

JJ: The trade will migrate even additional into digital options as new people who find themselves in all probability digital-first of their pondering come into the trade. There’s a want, nonetheless, to guarantee that these younger folks do in reality come into the trade. A lot of them probably have outdated perceptions of printing and packaging and don’t see how enticing it may be as profession at present. We can not lose sight of how essential it’s to herald recent expertise, and recent pondering, to proceed the trade’s digital transformation.

PW: At this time, what are the trade requirements for total gear effectivity (OEE)? What sort of return on funding ought to we count on from an OEE programme?

JJ: That may be a posh dialogue, and it might range by the actual print software. Actually the pattern is to construct automation into workflows and {hardware} in ways in which drive up the OEE of digital gear. Oftentimes, a buyer will purchase a more moderen, extra productive Vutek printer that may run a number of shifts with excessive utilization, changing two or three less-productive digital presses.

PW: Nozomi within the corrugated area is fascinating…

JJ: EFI has the biggest put in base – round 50 Nozomi presses worldwide – within the single-pass inkjet area for corrugated packaging.

One factor we have now seen in that market is that our Nozomi presses can drive OEE for analogue and digital gear. Clients that additionally do litho lamination or high-quality flexo can and do migrate a superb quantity of their work to digital with the Nozomi. The work they transfer to digital are sometimes current jobs that have been possibly solely barely worthwhile with litho lamination. However, when our packaging prospects try this, they find yourself freeing-up analogue capability, creating the potential to develop by growing OEE on each their digital and their analogue gear. The relative pace and ease in getting jobs into and thru manufacturing on a Nozomi press could make digital manufacturing best not only for short- and medium-run jobs, but additionally for versioned work, jobs which have exceptionally tight deadlines, and extra.

PW: India is a price-sensitive market, but the tendencies are eternally altering. As a mass producer of merchandise, how does one keep related, and what improvements in merchandise can one provide for customers to create tendencies or disrupt {the marketplace}?

JJ: Nicely, from a purely client sense, digital printing can assist manufacturers drive margin in price-sensitive areas. Digital additionally creates a path for smaller manufacturers within the client packaged items area to extend their presence and enchantment with shelf-ready packaging that rivals their bigger opponents’ choices. Digital additionally allows one-to-one; versioning and variable to be extra enticing to customers.

PW: Do you see remanufacturing as a comparable choice? One post-press gear producer has efficiently repurposed binderies within the Indian market. What’s your view – benefits versus disadvantages?

JJ: EFI has a big portfolio that provides us the chance to fulfill prospects the place they’re when it comes to funds and productiveness wants. This creates a relationship the place prospects can develop from entry-level manufacturing to very high-volume work. Remanufactured gear may be a part of that journey for some prospects searching for to enter the manufacturing show graphics market. Over time, we discover that remanufactured gear can spark the kind of development and alternative that leads a buyer to undertake the automation and different enhancements constructed into our latest printers. I’d view remanufacturing as an entrée for many who need to uncover new oceans.

PW: The F&B packaging market in India is predicted to develop from USD 33.2-billion in 2020 at a CAGR (compound annual development price) of 9.3% till 2026. We did a primary calculation that the consumption of packaged meals in India rose by 200% in the course of the earlier ten years, from 4.3-kg to eight.6-kg per particular person per 12 months. Moreover, the beverage trade accounts for round 23% of all PET purposes in packaging. The purpose is, consumption patterns are excessive in India. How does one handle a round financial system underneath such circumstances?

JJ: If development projections you’ve said for India proceed, there’s going to be much more emphasis on sustainability – with fibre-based packaging from renewable and recyclable sources as the important thing software. The round financial system is a part of the long run financial system, andit displays how digital, direct-to-board corrugated packaging printing on EFI Nozomi presses creates actual benefits. Nozomi presses devour 35% much less power than flexo, and Fogra has licensed Nozomi know-how to be probably the most power environment friendly digital corrugated manufacturing resolution its class. There are just about no VOCs in our LED inks for Nozomi presses, they’re GreenGuard Gold licensed, in addition to licensed for OCC repulpability and recyclability.

PW: How do you handle greenwashing as a part of your sustainability / round financial system communications?

JJ: We’re cautious about our analysis in claims as a result of we would like our prospects to make good, knowledgeable choices after they consider printing options. Within the packaging area, for instance, we took cautious steps working with Western Michigan College in america obtain OCC certification normal for recyclability.

Equally, we have now put the effort and time in to actually scrutinise the place our LED applied sciences evaluate when it comes to lowered power utilization, and Fogra has finished nice work analysing our LED know-how throughout our signage and packaging portfolios to element the power financial savings LED curing generates. Fogra discovered that the power financial savings utilizing our LED inkjet show graphics printers is as excessive as 82% in comparison with different digital printing strategies.

PW: The Authorities of India has set a imaginative and prescient of a USD 5-trillion financial system. In your view, what are the alternatives for the print and packaging trade – and your organisation – in India?

JJ: Development alongside that trajectory will imply rising requirements of residing in India, and with that, will increase within the sorts of advertising actions that demand high-quality, vibrant imaging. Over the previous 12 months or so we have now been excited to see extra exercise from our companions in India who promote EFI’s wide-format printers within the show graphics area.

PW: As and when the current USD 3.1-trillion financial system grows to a USD 5-trillion financial system, the Indian printing trade, significantly the packaging trade, will see substantial development. One quantity says, the packaging consumption in India has elevated 200% prior to now decade, rising from 4.3-kg per particular person each year (pppa) to eight.6-kg pppa as in FY20. How ready are you to help the print and packaging factories in India?

JJ: Within the print trade, you will notice EFI work with our prospects in India the methods we have now for many years when it comes to collaborating and fostering improved productiveness, greater high quality and effectivity. We attempt to all the time advance digital print in all the pieces we create. A lot of that has been by means of state-of-the-art workflows created in our Fiery product line – and lots of of our improvements from the Fiery enterprise are options developed at our facility in Bengaluru.

I count on the long run will see elevated curiosity and want for digital and automation in packaging to maintain up with development. India’s packaging trade will need and want to include extra digital printing, and never simply focus producing extra work on current, legacy analogue manufacturing traces. Sustainable, automated, environment friendly and high-quality digital manufacturing platforms are a part of the general evolution wanted to fulfill any predicted surge in packaging demand.

PW: In India, too many enterprise house owners speak about their machines and investments. Few deal with smooth energy. For instance, tradition, team-building, delegating, housekeeping, plus how one can get optimum conversion prices and be way more environment friendly. Your view?

JJ: I do suppose the deal with machines and investments develop into extra balanced with regard to the overall know-how ecosystem. All of us at EFI definitely share within the pleasure and appreciation prospects have when, for instance, they will develop into aggressive, coming into promising markets by putting in a few of our options.

That stated, I definitely can and do admire the significance of team-building, tradition, and delegating; they’re important to EFI’s personal success.

My profession has been in printing know-how, however for a few of that point I used to be in HR the place I had a hands-on function in team-building, recruitment, variety initiatives and extra. I admire how essential all of that’s to operating a profitable organisation.

EFI’s India Growth Centre (IDC) in Bengaluru – which is at present EFI’s largest international facility – exemplifies what we will do when it comes to teambuilding and tradition. The chief of the IDC, Samir Gulve, and his staff have made it a extremely progressive and centered operation. The power of the IDC is evident if you take a look at lots of the improvements it produces in our Fiery digital entrance finish and digital workflow merchandise, and in our IQ suite of cloud options.

PW: One take away out of your autobiography (in the event you write one) …

JJ: I’ve lived two lives that are very a lot intertwined.

I’m who I’m due to the inspiration my dad and mom constructed to mould me in my early years; and my spouse and two youngsters have made me the particular person I’m at present. My profession was enabled by the sacrifices made by my spouse and youngsters. From a profession standpoint, every day I attempted to commit myself to our prospects and staff members. A profession is a marathon of day by day sprints. I attempted to run onerous each day.

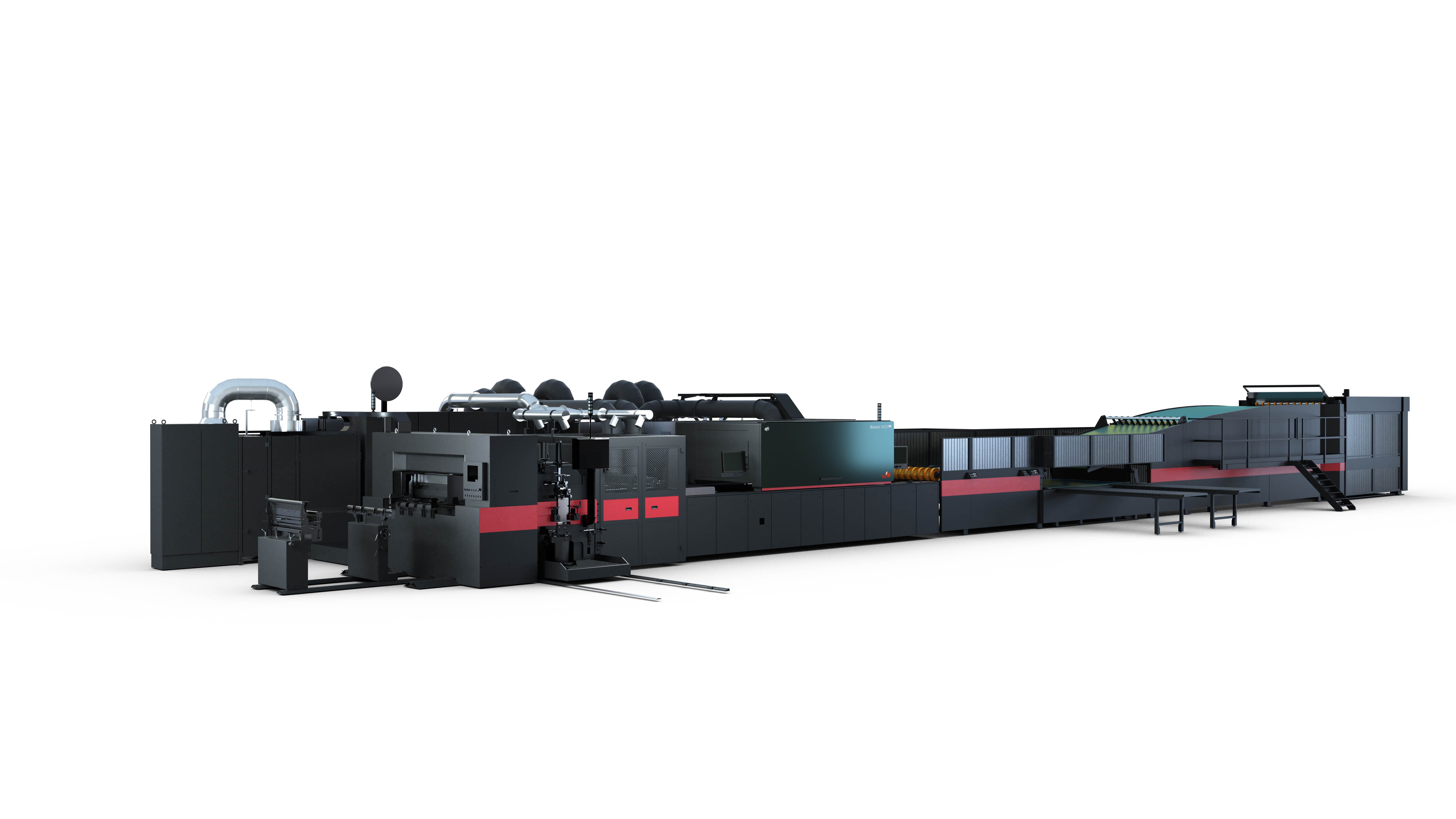

Product Highlight – EFI Nozomi 14000 LED

EFI Nozomi 14000 LED press is the latest ultra-high-speed inkjet resolution for the corrugated market. Out there this 12 months, the 55-inch-wide press runs at quicker speeds as much as 328-linear ft per minute with new productiveness modes, providing exceptional throughput whereas assembly corrugated packaging producers’ wants for extra compact manufacturing traces. The Nozomi 14000 LED affords packaging converters excessive uptime and might print practically all board flute varieties, with enhancements to robotically reject broken boards with out stopping print manufacturing.

Customers can select from a spread of configurations to enrich particular person wants, with single or twin backside feeder choices, a curler coater able to making use of various quantities of primer, an elective varnish station that enables for a spread of gloss or satin finishes, and full or bundle stacker choices. The Nozomi 14000 LED press is out there with as much as six colors, together with white.

The brand new press is provided with the most recent EFI Fiery NZ-1000 digital entrance finish (DFE) and likewise options the brand new Fiery system platform – Fiery FS500 Professional – enabling fast processing and color administration at full press speeds.

EFI Nozomi single-pass inkjet corrugated know-how charges excessive on energy consumption effectivity, in accordance with testing by the Fogra Analysis Institute for Media Applied sciences in opposition to the ISO 20690 power normal. Plus, EFI Nozomi is the one single-pass inkjet providing within the trade to have its output licensed for OCC recyclability and repulpability by the Western Michigan College Recycling, Paper and Coating Pilot Plant – a number one certification organisation for corrugated recycling.